Consoles Tailored for

Command Centers and Operators

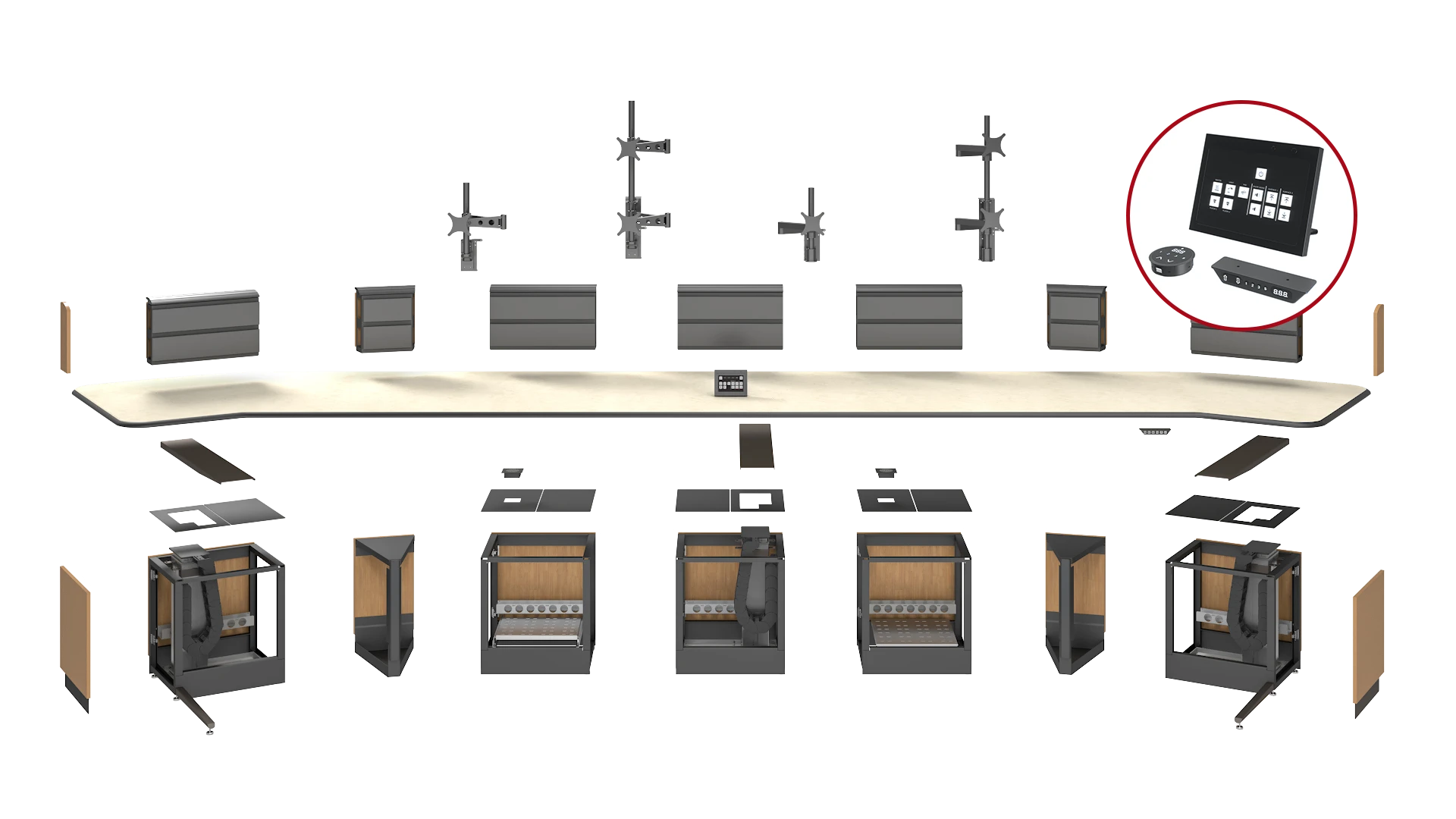

Our control room consoles are designed and built from the ground up to cater to the strict requirements of your operations. This means that they can vary widely in size, shape, functionality, and features. To accommodate such wide range of scenarios our consoles are designed with a modular structure to give maximum flexibility all while providing a robust backbone to sustain all your operational equipment.

In the following sections, we’ll delve into the most crucial parts of our consoles to gain a better understanding of how each component contributes to enhancing your control room needs. Additionally, we’ll provide instructions on how to operate our cutting-edge personal environment unit and share Tresco’s approach for designing and implementing consoles to fit any control room environment.

The following links let you jump right into any section that peaks your interest:

Understanding your Console

Let’s analyze the various components of our console to understand their purpose and how they integrate. This will help you use the console’s features more effectively, customize your control room operations, and improve operator efficiency.

Utilizing the features of our state of the art Personal Environment Unit

If your console is equipped with a personal environment unit, then you have access to the highest level of ergonomic comfort at the tip of your fingers. Let’s explore how to operate the system in the following video. We left out a couple of helpful links if you want to jump to specific features of the Tresco Personal Environment System.

Tresco Project Outline

At Tresco, we pride ourselves on our ability to properly elicit the requirements from your project stakeholders to build the foundation of your control room console transformation.

Our team of control console experts have the experience and knowledge to ask relevant questions to ensure your control room transforms into a functional and productive space for your operators.

The following are the key steps within out process:

- Project Initiation: Cadence, Timelines & Requirements

- Solution Design

- Approval & Sign-off

- Manufacturing

- Factory Acceptance Testing

- Logistics, Delivery & Install

- Project Approval & Closure

- Post-Install Care & Maintenance

Gain valuable insight into our process through the Tresco Project Outline whitepaper. This document showcases how we identify and address operational needs by developing strategic console solutions, and ultimately bringing them to life. Our consoles are built from the ground up to optimize your internal monitoring processes, helping you to achieve greater efficiency and mission-critical success.